Increasing the value of recycled organics

Our Circular Economy Research and Development Fund supported work by Gaia Envirotech to explore options to increase the value of recycled organics

This project aimed to address two key barriers that prevent anaerobic digestion from being commercially viable in Australia.

Product |

Modular composting and anaerobic digestion units |

Material classification |

Food and Garden Organic Waste (FOGO) |

Project type |

Trial and validation |

Research result |

The addition of food waste to animal manures significantly enhanced biogas and methane yields. |

Sector |

Organics recycling |

Grant recipient |

Gaia Envirotech |

SV funding |

$300,000 |

The outcome

Envirotech successfully increased the value of recycled organics by adding food waste to their animal manure anerobic digestor units. This led to higher biogas yields and improved compost quality.

The need

Gaia Envirotech, based in Ballarat, identified a need to improve the economic value of recycled organics to stabilise the organics sector and enhance client revenue.

They theorised that manipulating food and garden organic waste (FOGO) feedstocks could produce better compost and higher anaerobic digestion (AD) biogas yields.

Traditional equipment for separating high-value feedstock from FOGO is large, expensive, and unsuitable for modular waste processing. Therefore, Gaia Envirotech aimed to build a more suitable unit to increase the value of the end product and strengthen markets for products produced by their equipment.

The modular design of Gaia Envirotech composters makes them suitable for small-scale facilities.

The modular design of Gaia Envirotech composters makes them suitable for small-scale facilities. Developing the solution

To address the identified needs, Gaia Envirotech refurbished a dairy waste anaerobic digester to process food waste, and measure biogas output accurately.

The refurbished digester had:

- a digestate-biogas separation tank

- a new mixing system

- improved insulation

- larger biogas piping.

Food waste was then digested with cattle manure in the refurbished digester.

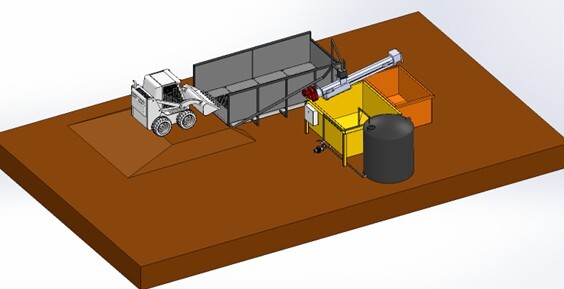

The team constructed equipment to separate the liquid component from FOGO. The FOGO Preprocessing Module (shown in the image below), consisted of a receival bay with a perforated floor, a pump, a macerating press screw and a storage tank. Liquid and small particles were forced through the perforated floor and pumped to the macerating press screw which separated the liquid and deposited it in a storage tank.

The contents of the storage tank were recirculated through the system to accumulate more organic matter. The biogas generation potential of the liquid was determined in the laboratory.

They purchased a Benenv MDS-101 multi-disc separator to de-water the digestate. A polyacrylamide powder was added to flocculate the digestate and aid the de-watering process. The end product known as digestate ‘filter cake’ was then analysed for total solids and moisture content.

FOGO preprocessing module design

FOGO preprocessing module design Future opportunities

Outcomes from this project provide further opportunities, including:

- more revenue for intensive livestock businesses

- higher value compost

- manipulating nitrogen levels in compost.

Download the project impact summary

Get in touch

Contact our Markets Acceleration team for more information.